4 Tips for Packaging Goods Transported by Air

Why is packaging important for air transport?

Packaging is essential when shipping goods by air to ensure your goods are transported safely without damage. Poorly packaged containers are estimated to cost the supply chain more than $6 million annually. TT Club also estimates that 65% of damage to goods is due to goods being poorly packaged, secured or obstructed.

Just consider the movements of your goods as it is transported by plane – there is handling by ground staff, interaction with vehicles such as trucks and forklifts and of course interference chaos on the plane itself.

Your shipment may also not be delivered on a flight. Instead, it may go through multiple processing points at different airports before reaching its final destination.

Proper packaging (and of course labeling) will also ensure the airline and ground staff understand if there are any restrictions surrounding your goods.

It is important to remember that any movement of the goods within the package poses a risk of damage during transport. The tighter the packaging, the safer it is and therefore the less likely it is to be damaged during the journey.

Top Tips for packing goods transported by air

In this section, we will outline tips to follow when packing goods for air transport. Putting these steps into practice can help you ensure the security and safety of your goods.

- Know the restrictions based on cargo size

Goods can be shipped in unit load devices (ULD), as palletized shipments, or as bulk cargo when transported by air. But there are a series of restrictions based on the height, length and width of your goods.

Maximum dimensions for standard air transport are 2.44 x 3.15m. You can certainly ship longer or wider goods, but these goods may need to be packed on special equipment.

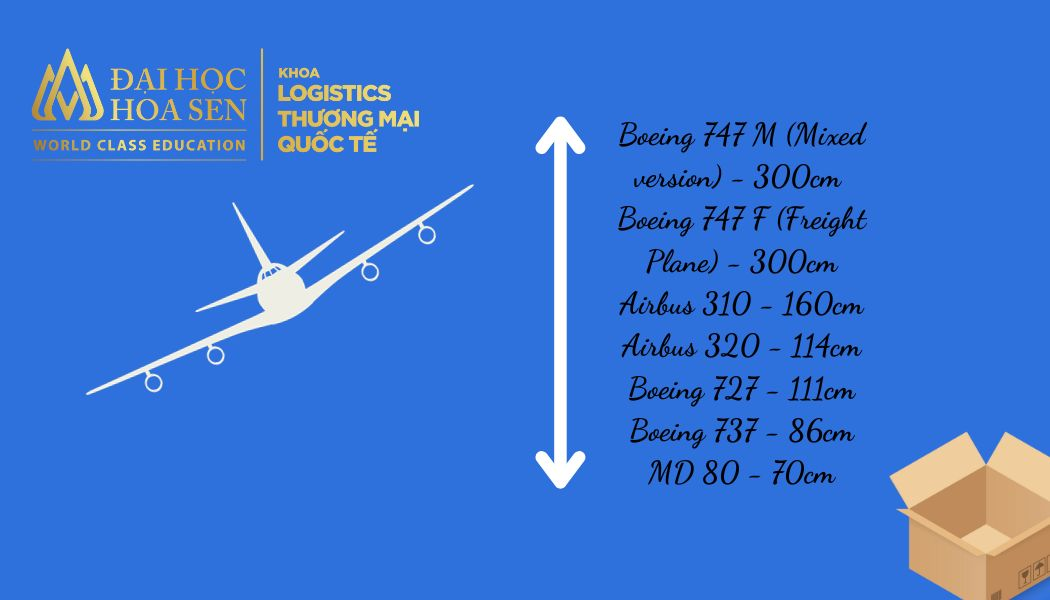

But the maximum height will also be determined by manual type as follows:

2. Understanding of aviation security regulations

Air transport security regulations specify that your goods must be inspected before export.

Your goods may be inspected:

As a package level inspection – where each individual box, carton or other item is inspected by a Regulated Air Cargo Agent (RACA).

Consolidated form – where homogeneous goods are packed on pallets, boxes are stacked and wrapped in plastic or in unit load devices (ULD).

As an Approved Known Shipper – air cargo originating from these companies does not require additional inspection before boarding.

As a general example, if your goods are palletized, they will need to fit the following dimensions to pass through the X-ray machine: 1.20m x 1.20m x 1.53m LWH, maximum 1000kg CW per pallet.

It is important to screen goods through metal detectors located on plastic or cardboard pallets, as wooden pallets will likely have nails.

3. Use a sturdy box

For air transport, you should use sturdy boxes to preserve your goods when transported by air.

You will need to note the main factors of the goods when packing them into boxes:

Weight – the type of aircraft your goods are transported in may have individual weight limits for each cargo, which will depend on the aircraft’s maximum takeoff weight (MTOW).

Moisture – consider all the factors that can cause moisture damage to your goods whether it is humidity, leaks or temperature changes.

Theft – there is always a risk of your goods being stolen. Therefore, for goods transported on airplanes, you should use plain boxes without brands or logos.

4. Use multi-layer boxes

Double-layer or triple-layer boxes are sturdy boxes with layers of cardboard stacked on top of each other. When you require extra protection for particularly fragile goods, these boxes are a preferred choice. These boxes are also sturdy enough to stack on top of each other and will provide the best protection for your goods. Note that sturdy plastic bags will also be accepted.